Caster wheels are widely applied in both industrial and commercial settings, bearing the weight of furniture or equipment and facilitating seamless mobility. As such, the selection of caster wheel material is a crucial decision that directly impacts its optimal performance, safety, longevity, and efficiency, as well as the level of protection for your floors, noise generation, and overall user experience.

In this guide, we’ll explore various materials commonly used in caster wheel manufacturing. By understanding the key factors, you can make informed decisions for the most suitable caster wheel material that aligns with your specific requirements and applications.

Different Types of Caster Wheel Materials

Polyurethane Caster Wheels

Polyurethane is a highly versatile material known for its exceptional durability. Caster wheels made from polyurethane are widely recognized for their remarkable long-lasting and load-bearing capacity. They offer excellent resistance to abrasion, vibration, chemicals, and oil, making them one of the most commonly used types of casters available in the market today.

The oscillatory properties of polyurethane minimize rigidity, allowing wheels to absorb force, ultimately adding the load-bearing capacity. But they not only excel in withstanding medium to heavy loads but also deliver great surface protection. They are gentle on floors and do not leave marks or scuffs, which are extremely suitable for keeping sensitive surfaces, like hardwood, laminate, or tile, in pristine condition.

While polyurethane caster wheels usually come with higher price tags, their performance is sufficient to justify the increased cost – as an ideal long-term investment. They are a popular choice for industries that require better reliability in high-pressure situations, including manufacturing, warehousing, automotive assembly lines, etc.

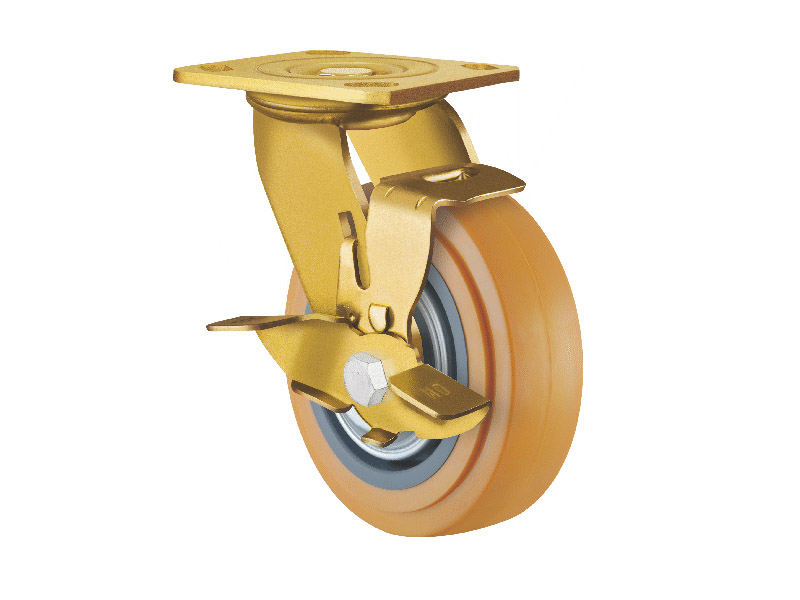

Heavy Duty Caster With 400Kg Load Capacity

Rubber Caster Wheels

Rubber caster wheels are prized for their superior traction and shock absorption capabilities for residential and commercial environments. They are especially valuable when navigating uneven or delicate surfaces, such as hospitals, laboratories, and institutions.

In addition to smooth and safe maneuverability for controlled movement, the natural rubber elasticity helps absorb shocks and vibrations. They provide a more silent operation than more rigid materials like steel or nylon, making them great for offices, clinics, libraries, and various settings where noise reduction is essential.

However, rubber caster wheels have limited weight capacity and may not be suitable for heavy loads or industrial settings requiring high-weight capacities. Additionally, poor-quality rubber caster wheels can develop flat spots when left stationary under a heavy load for extended periods, resulting in reduced mobility and uneven rolling.

Utility Cart Rubber Caster Wheel

Nylon Caster Wheels

Nylon is a lightweight material that can help to reduce the overall caster weight, making it easier to maneuver and transport items on nylon caster wheels. Moreover, its low rolling resistance contributes to smooth and effortless movement on different surfaces.

What’s more, nylon caster wheels are a great option for environments where exposure to chemicals, oils, and solvents is common due to their excellent resistance to these substances. Besides, made from non-corrosive material, they are well-suited for use in damp or humid conditions where concerns about rust and corrosion may arise.

In general, nylon casters are harder than rubber or polyurethane ones, which may result in potential floor damage. They may also tend to generate more noise during operation due to their hardness. If noise is a concern, it is best to choose caster wheels made from quieter materials.

Swivel Caster With Nylon Wheel

Factors to Consider When Choosing Caster Material

Load Capacity

Before selecting caster wheel material, it’s vital to determine the load-bearing weight of the caster wheels needed to support and carry. A mismatch between material and load can lead to premature wear and frequent replacements, impacting safe handling and operational efficiency.

Flooring Type & Protection

The type of flooring in your environment is a critical factor – different materials offer distinct levels of floor protection. Analyze the compatibility of your chosen material with the specific surfaces in your workplace to avoid damage and maintain a safe working environment.

Environmental Conditions

Consider the environmental conditions your caster wheels will be exposed to. Extreme temperatures, moisture, and chemicals can affect different materials. Evaluate the conditions your caster wheels will face to ensure they perform optimally in their intended environment.

Top-quality Caster & Wheel Manufacturer

Noise levels & vibration

When selecting, it is important to assess the amount of noise and vibration they produce. Softer materials such as rubber and polyurethane generate less noise than harder materials like steel or nylon. If noise reduction is a priority, it is recommended to select caster wheels made of materials that operate quietly.

Cost vs. Long-Term Investment

When deciding on caster wheel material, it’s tempting to focus solely on the initial cost. However, it’s crucial to think about the long-term investment. Cheaper materials may require frequent replacement, resulting in higher maintenance costs over time. Investing in durable, high-quality caster wheels might be pricier upfront but can yield substantial long-term savings and a superior return on investment.

Conclusion

In a word, each caster wheel material has unique properties and advantages. Selecting the right material for caster wheels is a multifaceted decision that demands careful consideration of various factors – but it all comes down to what you need.

Inford is the leading caster wheel manufacturer and supplier in China. Our team has extensive knowledge and experience in casters and wheels to provide perfect caster solutions for your unique requirements. Please feel free to contact us at infordcaster@vip.163.com to learn how Inford’s high-quality caster products and services help you achieve optimal mobility and efficiency in operations!