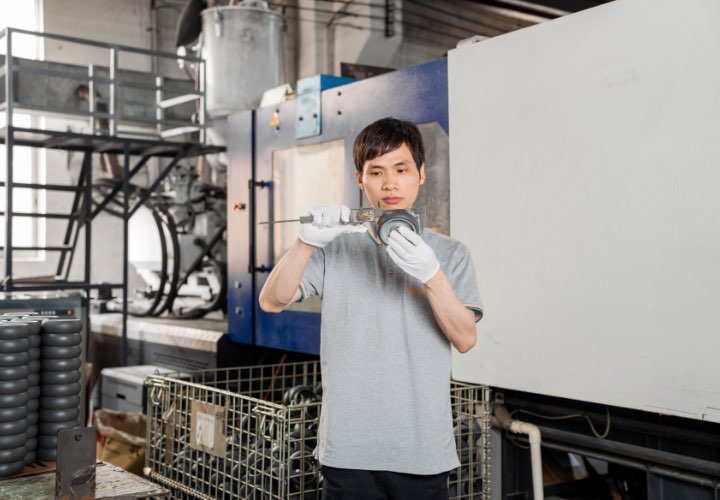

The quality of your casters is fully guaranteed from the moment you place the order. Each product undergoes a closed-loop inspection before it is shipped. Multiple departments, including the technical department, the production department, and the quality center, work together to ensure the quality of our products.