In the dynamic landscape of industrial operations, the delicate balance between mobility and stability has always been a crucial aspect. Whether in manufacturing facilities, warehouses, hospitals, or even your local supermarket, the seamless movement of equipment is often indispensable. This is where heavy-duty locking casters come into play to improve both productivity and safety significantly.

Understanding Heavy-duty Locking Casters

Castors, the less noticeable wheels affixed to various apparatuses, play a vital yet underappreciated role in facilitating industrial mobility. These understated elements are instrumental in determining the ease of moving equipment. Employed in a vast array of applications, from tool storage units to hospital beds, castors function as the driving force behind literal and figurative mobility.

While casters come in a variety of sizes and configurations, heavy-duty casters take the lead when it comes to bearing substantial loads. They are specifically designed to withstand the wear and tear of industrial environments, ensuring longevity and resilience. By utilizing heavy-duty caster wheels, your equipment remains mobile even under the harshest conditions.

Now, the introduction of locking mechanisms adds an interesting dimension to the idea of mobility. Heavy-duty casters with brakes have specialized braking mechanisms that offer more than just mobility but stability on demand. This securely immobilizes equipment, preventing unexpected movements and potential accidents.

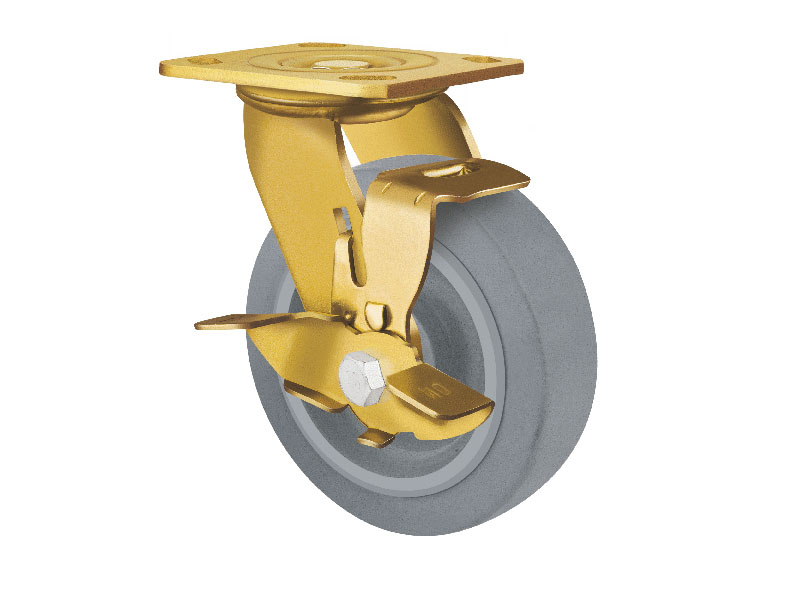

Heavy-duty Swivel Caster With Metal Side Brake

Types of Locking Mechanisms

Total Locking Casters

Total locking casters provide a comprehensive solution, locking both the wheel and the swivel mechanism. They are commonly used in industries that require safety and control, like healthcare settings, laboratories, industrial environments, and other situations.

This type is ideal for equipment that requires maximum stability and cannot tolerate any movement, such as when the equipment needs to stay stationary during use to avoid unintended movements or to ensure safety in certain applications.

Directional Locking Casters

Directional locking casters allow you to lock the wheel’s swivel while still enabling linear movement. They are perfect for scenarios where you need to move equipment in a straight line without any unintended pivoting, delivering enhanced control over the direction of movement.

These casters are highly advantageous in environments like laboratories, where sensitive instruments and equipment need to be transported with precision. Directional locking swivel casters provide the necessary stability to avoid any sudden movements that could damage delicate samples or research equipment.

600kg/1300lbs Load Directional Lock Caster

Braking Mechanisms

Braking mechanisms can be applied to wheels to slow down and even stop their movement. While not technically casters, braking mechanisms are often used in conjunction with casters to enhance stability. They give a straightforward way to stop the movement, particularly in situations where temporary immobilization is needed.

Benefits of Heavy-duty Locking Casters

Enhance Mobility and Maneuverability

Heavy-duty locking casters combine the best of both worlds. These dynamic components enable equipment to move with agility when needed. At the flick of a lever or push of a pedal, they can be locked into place to provide a secure foundation. This unique duality empowers workers to position and reposition equipment with ease, enhancing overall operational efficiency.

Ensure Stability and Safety

Safety is paramount in any industrial setting. Heavy-duty swivel casters with brakes, particularly directional control ones, provide an added layer of security by preventing equipment from rolling unexpectedly. Whether it’s a medical cart in a hospital or a bulky toolbox in a workshop, heavy-duty lockable casters ensure that when equipment needs to stay put, it stays put, providing safety and stability.

Versatile Applications Across Industries

Heavy-duty locking casters find their places in various demanding environments, enhancing the productivity, efficiency, and safety of diverse industries.

Manufacturing facilities: Heavy-duty lockable casters allow easy movement of heavy loads or machinery, ensuring efficient workflow. Once in position, the casters can be locked for stability and to prevent accidents or damage.

Heavy-duty Caster Wheel Solutions

Warehouses: Workers can reposition racks, shelves, and carts as needed quickly with heavy-duty locking casters, optimizing storage space and facilitating inventory management. The casters can be locked once the items are in place to avoid any undesirable shifting or toppling.

Healthcare settings: Heavy equipment such as medical carts and beds need to be moved between rooms and floors. Heavy-duty locking casters on this equipment ensure stability during procedures and patient transfers.

Factors to Consider When Selecting Locking Heavy-duty Casters

Load Capacity

The primary consideration when choosing heavy-duty locking casters is their load-bearing capacity. Make sure the casters can support the weight of your equipment without compromising stability.

Material and Durability

The durability of casters is a critical factor. Look for casters made from robust materials such as stainless steel or high-grade polymers to ensure they withstand the rigors of your industrial setting.

Swivel vs. Rigid Casters

The choice between swivel and rigid casters depends on your specific needs. Heavy-duty swivel casters with brakes offer greater maneuverability, while rigid ones enhance stability. Your choice should align with the intended application.

Ergonomics and Noise Reduction

Consider the ergonomics of the locking mechanisms and their ease of operation. Additionally, opt for casters designed to reduce noise, ensuring quieter and more pleasant working conditions to enhance comfort and efficiency.

Stainless Steel Rigid Caster With Brake

Conclusion

In a word, heavy-duty locking casters serve as the guardians of both mobility and stability in the industrial field. They seamlessly combine agility with security, ensuring that equipment remains where it’s meant to be when it’s meant to be there.

Whether in healthcare, manufacturing, or any other industry, these casters are a testament to their commitment to safety and efficiency. If you are in need of quality heavy-duty lockable casters for your equipment, Inford is here to assist you! For more information, please don’t hesitate to reach out to us at infordcaster@vip.163.com.